Star CNC SR-16 Swiss-Type Lathe (2008) | Affordable Machine Tools for Sale

MACHINE SPECS

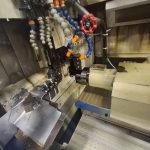

The Star SR-16 Swiss-type automatic lathe delivers unmatched precision, reliability, and proven performance. Known throughout the industry for its durability and consistent accuracy, the SR-16 remains a trusted choice for shops that demand tight tolerances and efficient production.

Though the Star SR-16 has been discontinued, it continues to hold strong value on the used CNC market. Many shop owners prefer this model for its compact footprint, straightforward operation, and long-term dependability — making it a cost-effective entry point into Swiss turning or a reliable addition to an existing production line.

Why Choose the Star SR-16?

Investing in a used Star SR-16 CNC lathe is a smart move for manufacturers looking to maximize value without sacrificing capability. The SR-16 is built for high-volume, precision part production — especially for components use din medical, aerospace, and electronics industries.

With its rigid design, excellent repeatability, and ability to maintain micron-level precision, this machine continues to outperform expectations. It’s easy to set up, simple to maintain, and well-supported by an active secondary market for parts and service.

| Specification | Details |

| Max. Turning Diameter | 16 mm (5/8 in) |

| Max. Headstock Stroke | 205 mm (8 in) |

| Max. Drilling Capacity (Stationary Tool) | 8 mm (5/16 in) |

| Max. Drilling Capacity (Power-Driven Attachment) | 5 mm (3/16 in) |

| Max. Tapping Capacity (Stationary Tool) | M8 × P1.25 |

| Max. Tapping Capacity (Power-Driven Attachment) | M5 × P0.8 |

| Max. Milling Capacity | 10 mm (25/64 in) |

| Max. Die Cutting Capacity | M8 × P1.25 |

| Max. Slotting Capacity | 1.5 mm (W) × 4 mm (D) |

| Main Spindle Speed | 500 – 10,000 rpm |

| Sub Spindle Speed | 400 – 8,000 rpm |

| Main Spindle Motor | 2.2 kW (continuous) / 3.7 kW (30 min) |

| Main Spindle Bore | 20 mm (25/32 in) |

| Number of Tools | 5 tools + 3 power-driven tools |

| Tool Shank Size | 12 × 95 – 120 mm / 12.7 × 95 – 120 mm |

| Power-Driven Attachment (Cross Milling) | 350 – 5,000 rpm |

| Power-Driven Attachment (Slotting) | 60 – 900 rpm |

| Power-Driven Attachment Motor | 0.4 kW |

| Servo Motor | All axes absolute pulse coder |

| Main Spindle Center Height | 1,060 mm |

| 3-Spindle Endworking Attachment | 3 tools |

| • Max Drilling Capacity | 8 mm (5/16 in) |

| • Max Tapping Capacity | M8 × P1.25 |

| • Max Die Cutting Capacity | M8 × P1.25 |

| Coolant Tank Capacity | 100 L |

| Hydraulic Tank Capacity | 20 L |

| Hydraulic Pump Motor | 0.75 kW |

| Coolant Motor | 0.18 kW |

| Power Consumption | 5.0 KVA |

| Machine Dimensions (L × W × H) | 2,200 × 1,255 × 1,735 mm |

| Machine Weight | 1,700 kg |

Key Features of the Star SR-16:

- Proven Swiss-type turning performance trusted by machinists worldwide

- Compact, efficient design ideal for smaller production floors

- High-speed spindles ensure superior surface finishes & tight tolerances

- Simplified setup and reliable long-term operation

- Exceptional value in the used CNC market

Smart Investment for Growing Shops

Even though the Star SR-16 is discontinued, its reputation for precision and reliability lives on. Many shops find that a used SR-16 Swiss lathe offers the perfect balance of affordability and production capability, especially for those expanding capacity or looking to standardize on Star equipment.

Buying a used CNC Swiss lathe like the SR-16 is not just cost-effective — it’s a strategic decision that can help boost productivity and reduce overhead without the price tag of a new machine.

Note: Specifications Are Estimations, Subject to Verification